Torsion Springs

US-Based Torsion Spring Manufacturing, Stock & Custom Springs, Fast Turnaround

Components manufactures and stocks torsion springs in hundreds of sizes, including single, double, and small torsion springs. Many in-stock parts ship the same day, and custom designs are engineered and delivered to your specifications with expert support. Choose from brass, steel, stainless steel, titanium, and specialty alloys. Bulk pricing, short lead times, and rapid quotes are available to help you move from design to delivery faster.Ėý

In-Stock Torsion Springs

Browse our inventory of torsion springs for sale. We have hundreds of in-stock torsion spring designs that ship the same day. Click to filter results by material, diameter, and other parameters. Filter Results

The Highest Quality Standards

ISO9001

Certified for Quality Parts

AS9100D

Certified for Industry Needs

RoHS

Compliant for Peace of Mind

Quality Inspections

For Optimal Performance

TORSION SPRING MANUFACTURER

Custom Torsion Springs

Stock torsion springs not meeting your needs? Whatever your requirements, weâll work with you to design and prototype a custom torsion spring to meet your exact specifications. Components teams are expert spring manufacturers and can support traditional torsion spring manufacturing needs as well as double torsion springs and other unique designs. Our engineers can advise on optimum dimensions and winding together with materials, finishing, corrosion resistance, and production processes for industrial torsion springs and more. Get in touch with one of our experts to discuss your needs.

Torsion Spring Manufacturing

As one of the most experienced and versatile torsion spring manufacturers in the United States, our torsion springs can be made in a variety of wire diameters and shaped. Our production capabilities also support most bend types and orientations in the diameters below.

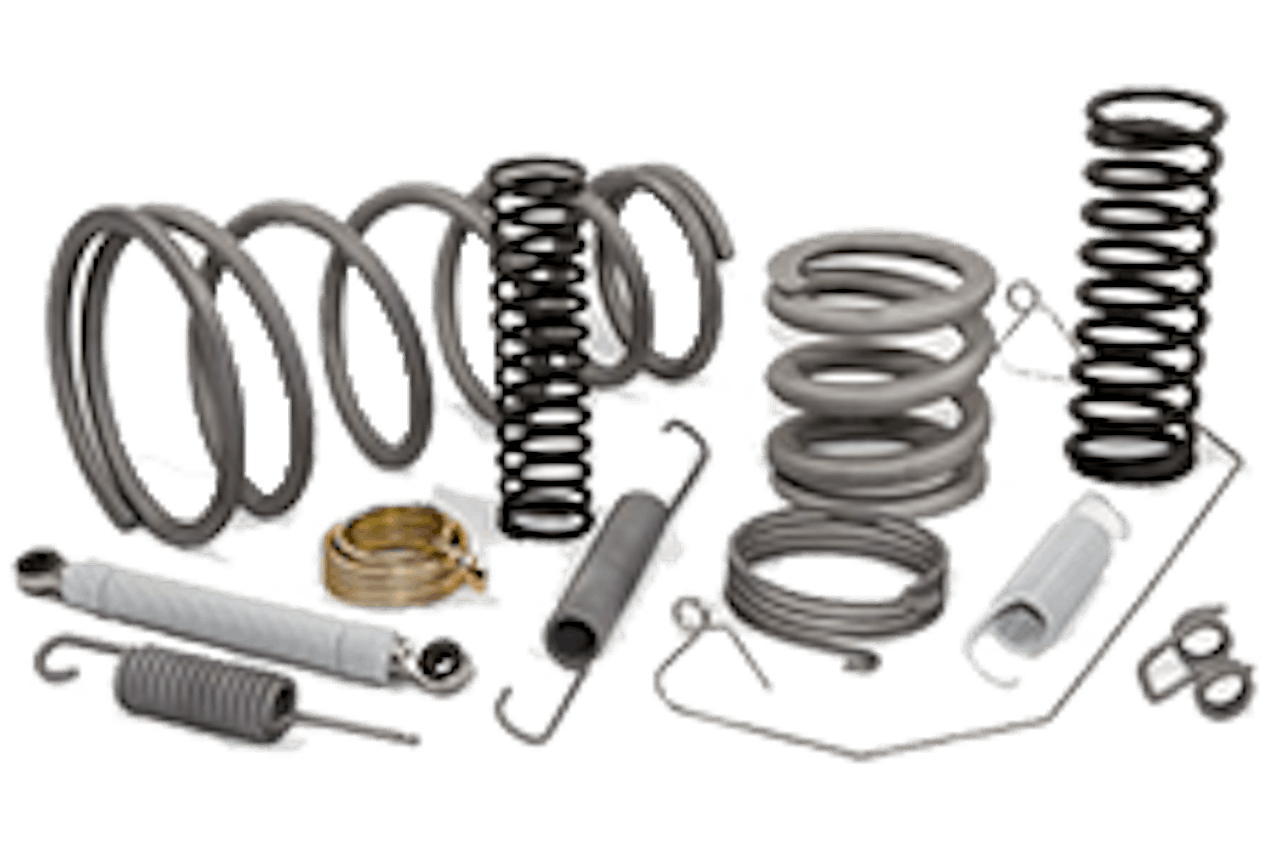

- Single torsion springs in wire diameters from: .008"-.625"

- Double torsion springs in wire diameters from: .008"-.236"

- Wire shapes: standard, rectangular, and square

Torsion Spring Materials

Brass and steel are the most common torsion spring materials. However, the alloy selected for wire production is determined by the application, weather, temperature and other environmental considerations. Don't see what you need? Contact us for a full list.

Torsion Spring Finishes

We offer a range of finishing processes and industrial-grade finishes that help torsion springs resist corrosion and increase lifespan. We also provide packaging solutions to enhance product handling and workflow efficiency

Torsion Spring FAQs

Where can I buy stock torsion springs?

Where can I buy stock torsion springs?

Components maintains one of the industry's largest inventories of in-stock torsion springs, with same-day shipping available for many parts. Our catalog includes single, double, and small torsion springs in a variety of wire diameters, materials, and left or right wind directions. We even offer a selection of optional finishes that can be applied to your order, including black oxide, gold iridite, and zinc.Ėý

Use our online filters to find the exact part you need by size, material, or orientation.Ėý

Ėý

Where can I buy custom torsion springs?

When you need a custom spring, Components offers entirely custom spring engineering, including expert engineering support from a variety of knowledgeable in-house manufacturing and engineering experts. Our team will work with you to optimize torque, coil count, material, and finish for your application, from prototyping to high-volume production.Ėý

No matter where you are in the design process, we can assist. Simply request a custom quote to begin, and we'll work with you to optimize your current design or develop something entirely new. Ėý

Most of our in-stock torsion springs ship the same day your order is placed. For custom spring orders, lead times depend on the complexity of the design, whether prototypes are needed, and the material and finish requirements (standard vs. specialty). Typical production takes between 4-6 weeks; though expedited production is possible for urgent projects. Contact us to discuss timelines.Ėý

Yes - bulk pricing applies at higher volumes, and our engineering team can optimize designs for cost-efficient production. Pricing tiers and MOQs vary by spring size and material. Request a quote to learn more.

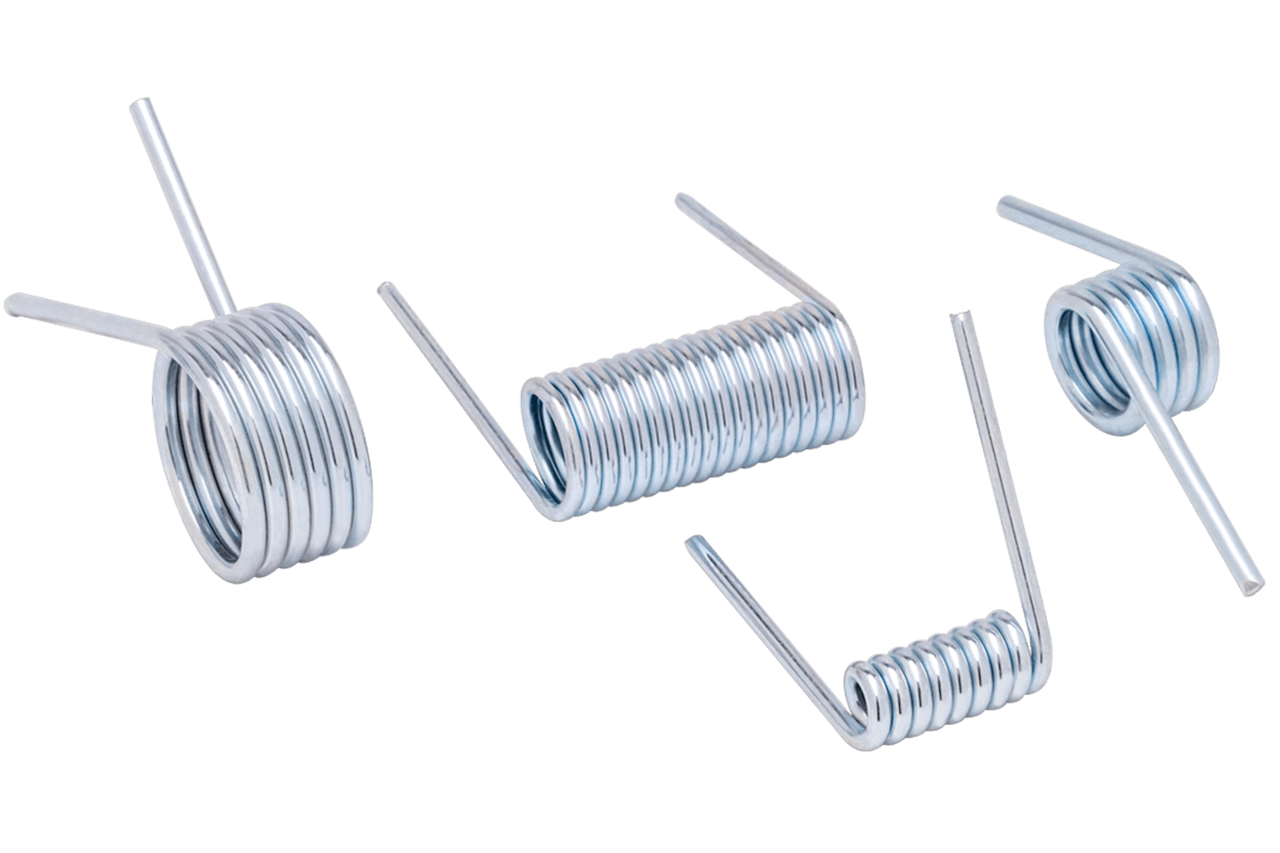

A torsion spring is a type of coiled spring that exerts a twisting force, or torque, along a central axis. Depending on the application, torsion springs can be designed to work in a clockwise or counter-clockwise rotation, thus determining the direction of the wind.Ėý

A torsion spring is a type of coiled spring that exerts a twisting force, or torque, along a central axis. Depending on the application, torsion springs can be designed to work in a clockwise or counter-clockwise rotation, thus determining the direction of the wind.Ėý

offers a selection of stock and standard torsion springs with legs of equal length oriented at varying unloaded angles, as well as custom torsion spring manufacturing.

What makes torsion springs unique?

Torsion springs are unique because they store mechanical energy through twisting rather than stretching or compressing. This allows them to exert a torque when turned, making them ideal for applications like closing doors, retracting mechanisms, and in various automotive components. Their design enables them to deliver a significant amount of force in a compact form, making them versatile for both small and large devices. Additionally, the precise engineering involved in their manufacturing allows for customization in terms of size, material, and strength.

Torsion springs work by storing and releasing angular energy or statically holding a mechanism in place by deflecting the legs about the body centerline axis. They offer resistance to twist or rotationally applied force. A spring of this type will reduce in body diameter and increase slightly in body length when deflected in the preferred direction of the fabricated wind.

Torsion springs are used in a wide variety of applications. Some of the most common include garage door torsion springs and door hinge torsion springs. Other uses may include clothespins, levers, and clocks, as well as use in the automotive, medical, and industrial manufacturing industries.

The life expectancy of a torsion spring largely depends on its material, design, and the amount of stress it endures during operation. The majority of torsion springs last 10-15 years, or a minimum of 5,000 to 25,000 cycles. High-quality torsion springs made from durable materials can last anywhere from several thousand to millions of cycles, depending on the specific application. Factors such as environmental conditions, frequency of use, and the magnitude of applied torque also play significant roles in their longevity. Regular maintenance and proper installation can further extend their lifespan, ensuring reliable performance over time.

Tolerance values for torsion springs depend on the body-diameter to wire-diameter ratio and are about +/- 10% in torque and +/- 5% in diameter.

The torsion spring configuration is designed for the purpose of storing and releasing angular energy or for the purpose of statically holding a mechanism in place by deflecting the legs about the body centerline axis. A spring of this type will reduce in body diameter and increase slightly in body length when deflected in the preferred direction of the fabricated wind.

Ėý

When designing a torsion spring, it's important to consider your application and whether you will need round, rectangular, or shaped wire, like square wire. The simplest and most common torsion spring designs are single body torsion springs made from rectangular wire with straight ends, although this design format can be modified with bends and formed shaped.

The direction of the fabricated wind can also be important for torsion spring applications due to the leg bearing/attachment location having to be on the left or right side upon assembly. A torsion spring is normally supported by a rod (mandrel) that is coincident with the theoretical hinge line of the final product.

Double torsion spring designs are more complex, and the manufacturing method will need to be considered. Double torsion springs are coiled from the center, as opposed to single torsion springs, which are coiled from the ends. For details on torsion spring design for both single and double body torsion springs, reach out to our engineering team through our Ask an Expert form.

Correct dimensions are crucial in identifying the right spring for your application. Use the steps and diagram below to accurately measure your torsion springs.

- Hold the spring in one hand and the calipers in the other hand.

- Place the caliper âteethâ on the inside diameter. This is called the Inside Diameter (I.D.).

- Place the calipers on the âlegâ to measure the wire. This is called Material Size (or Wire Diameter).

- Place the calipers on the working coils of the spring. This is called the Body Length. Place the calipers on the working coils of the spring. This is called the Body Length.

- Count the total coils, beginning at one end, just under where the leg leaves the body. Count to the other end, all full coils, and any fraction thereof. This is called the Number of Coils and determines leg position. i.e. 90°, 180°, etc.

- Determine the direction of the coil (Wind Direction). See diagram for hand/finger illustration. Right Hand Wind or Left Hand Wind.

There are single body torsion springs and double body torsion springs. A single body torsion spring has one core coiled area with two ends. A double body torsion spring has two coiled areas connected by a bridge. Each body in a double torsion spring has one end that can be tailored to individual needs.

Ėý

Double torsion springs have a number of advantages over single torsion springs, including greater strength and the ability provide more force. They are frequently used in

Single body torsion springs are common across manufacturers, but it is rare to find a double body torsion spring manufacturer. offers both single and double body torsion springs.

Configurations & End Types

Torsion Spring Configurations

Torsion springs can be configured in several distinct ways to meet specific application needs, including straight torsion springs, straight offset torsion springs, and hinged torsion springs. Straight torsion springs have a simple, uniform design, allowing for effective torque generation along their length. Straight offset torsion springs, on the other hand, feature an offset design that can provide additional clearance or fit in tighter spaces while still delivering necessary rotational force. Hinged torsion springs are equipped with a hinge mechanism, enabling them to pivot and provide controlled movement, making them ideal for applications like door closers. Each configuration offers unique advantages and can utilize different end types.

Torsion Spring End Types

Like other coiled springs, torsion springs can have a variety of end types depending on the application and industry they're used in. Some of the most common end types include straight, hook ends, and hinge ends. Custom or specialty ends can also be produced by custom torsion spring manufacturers like Components.

Torsion Spring Resources

Visit our to see tips and tricks for how to design and engineer torsion springs and other Components parts.