Extension Springs

US-Based Extension Spring Manufacturing

Extension springs are used in nearly every industry and are ideal when a precise amount of force is required at a certain deflection. manufactures stock, standard and custom extension springs. Stock products ship same-day, and we offer nearly every size, material, and wire diameter for custom products.

Ėý

Custom Extension Springs

Quick quote turnaround

Expert engineering and design support

Rapid prototyping and delivery

Ėý

316 Extension Springs

Medical-grade 316 stainless steel

In-stock with same-day shipping available

ODs from 0.063" to 0.25"

Long Extension Springs

Lengths from 20" to 26"

In-stock with same-day shipping available

302/304 stainless steel and carbon steel

In-Stock Extension Springs

Browse our inventory. We have thousands of in-stock extension spring designs that ship the same day. Click to filter results by material, diameter, and other parameters. Filter Results

Superior Products & Support

29

Locations in the USA

102

Engineers at Your Service

40,000

Extenstions Spring Designs In-Stock

Unlimited

Custom Spring Capabilities

Custom Extension Springs

specializes in custom fabrication of extension springs and has vast manufacturing capabilities beyond our competitors; whether you require a spring with extreme length, heightened performance, or quality certified products, we have you covered.

Our solutions approach is not limited to manufacturing. We specialize in prototyping, design, and tooling. We will work with your team and preferred specifications to assist you in developing the best spring for your application.

Extension Spring Manufacturing

If you are looking for top extension spring manufacturers with industry-leading expertise, youâve come to the right place. Our teams are comprised of experienced manufacturing technicians and engineering experts who are committed to developing the right products to suit your needs. Our experts can produce extension springs of various thicknesses and lengths using both cold and hot coiling processes.

Another advantage of working with is that we maintain stock of numerous alloys. The advantage is that if a couple of prototypes are needed, our in-house stock gives us the ability to develop them in a cost-effective way.

Materials

We also offer a variety of treatment and finishing options for custom springs made from standard or specialty materials. Certifications of conformance for geometric tolerances for stock springs are available upon request. Material certifications are available for custom springs.

Finishes

Our extension springs can be manufactured with a selection of commonly requested or specialty finishes.

Wire Types

We produce extension springs from both bar and wire stock in a variety of thicknesses through both hot and cold coiling methods. More details are listed below:

WIRE TYPE & DIAMETER

- Wire and Bar Stock: 0.008" - 0.750"

Direction of Helix (Wind)

We can configure your extension springs in either a left or right wind configuration to suit your specific application.

WIND DIRECTIONS

- Left

- Right

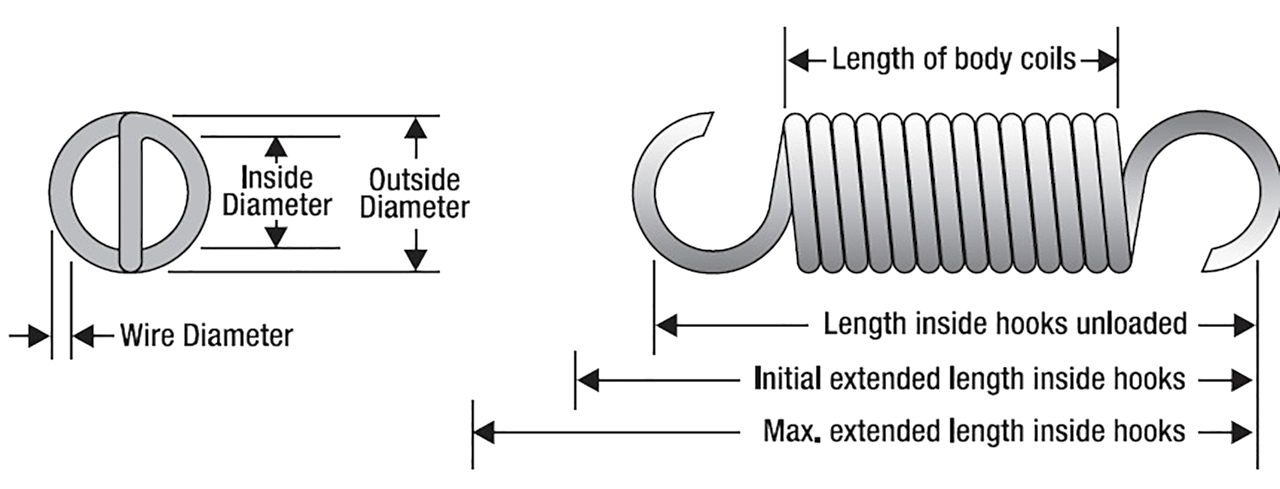

Measurements

To accurately measure an extension spring, follow the steps below.

- Hold the spring in one hand, and the calipers in the other hand.

- Place the calipers across the outside coil, either at the end or the center of the spring. This is called the Outside Diameter (O.D.).

- Place the calipers on the wire at one end of the body coil of the spring. This is called the Wire or Material Size.

- Place the calipers (or tape measure) on the full length of the spring, inside the hooks. This is called the Length (L.I.H.). (see diagram for example)

Extension Springs FAQs

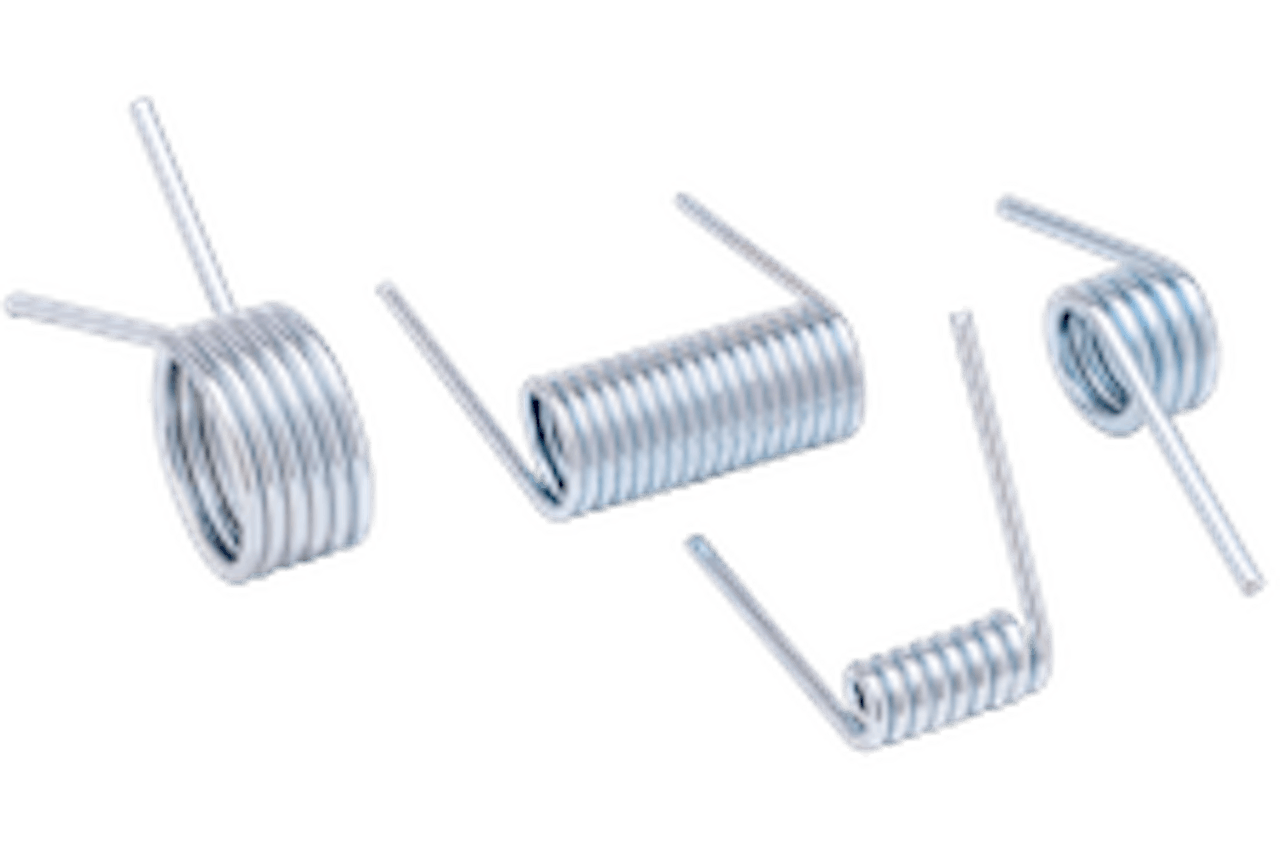

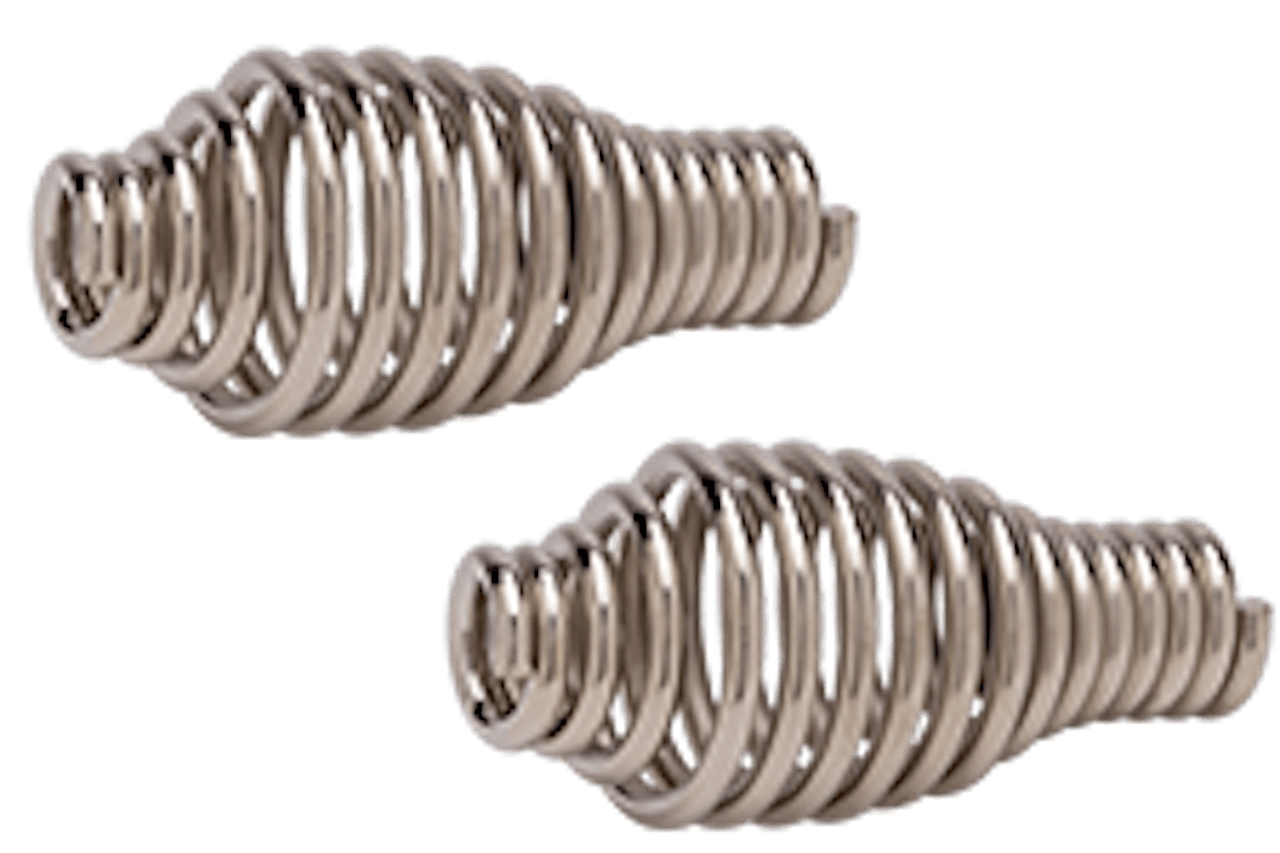

Extension springs are tightly wound coils designed to store and release energy by resisting pulling forces. When extended, they create a force that pulls objects back to their original position. Common applications range from garage doors and trampolines to medical devices and industrial machinery.

Extension springs are designed to absorb and store energy as well as create a resistance to a pulling force. The âinitial tensionâ is created during manufacturing when the wire is rotated backward during coiling. It is the initial tension that determines how tightly together an extension spring is coiled. When you pull the spring apart, you are undoing the rotation, which develops force or initial tension. Initial tension can be manipulated to achieve the load requirements of your particular application.

Extension springs are used in a wide variety of applications where a precise amount of force is required at a certain deflection. Extension springs are used to retract aircraft landing gear, to tether equipment to oil rigs in offshore applications, and on Class 8 heavy trucks as hood-assist springs to safely hold the hood in place for engine maintenance. Other examples include specialized springs implanted in roadways or around secure buildings to create barriers to provide additional protection from possible outside threats. They can range dramatically in length (from 1/2-inch to 50 feet) and in the force they create (from a few ounces to thousands of pounds).

Extension springs are found in countless products and industries, such as:

- Automotive: brake assemblies, interior components

- Aerospace: control mechanisms

- Appliances: washing machines, refrigerators

- Industrial equipment: levers, latches, and counterbalances

- Consumer goods: trampolines, toys, and fitness machines

While both are helical springs, their functions differ as below:

Extension springs work under tension, resisting pulling forces.

Compression springs work under pressure, resisting pushing forces.

Choosing between the two depends on whether your application requires resistance to pulling or pushing.

For more details, review this in-depth guide covering The Difference Between Extension Springs & Torsion Springs.

Spring rate, or stiffness, is the amount of force required to extend the spring by a specific distance. It depends on factors such as wire diameter, coil diameter, material type, and number of coils. Engineers also account for initial tension, the force required to begin separating the coils.

Extension springs are most often manufactured from:

- Music wire for high strength and fatigue resistance.

- Stainless steel for corrosion resistance in harsh environments.

- Phosphor bronze or other specialty alloys, when conductivity or non-magnetic properties are required. The right material choice depends on load requirements, environmental exposure, and desired lifespan.

The ends on the extension springs offered in our stock inventory are the common machine-made hook and full-loop configurations and include many varieties of extension springs with hook ends. The hooks or loops may have an across center transition of the last coil before forming the hook or loop. The angle between hook/loop planes (end position) is random. If you need a specific end configuration, contact us for design support and quoting.

Common End Types:Ėý

- Machined Ends

- Across Center Ends

- Double Full Loop Ends

- Side Hook Ends

- Extended Ends

Initial tension is the pre-load force built into an extension spring. It determines how much force is needed before the coils begin to separate. Properly balancing initial tension is critical for predictable performance in applications requiring accuracy and reliability.

The lifespan of an extension spring depends on material selection, design parameters, and environmental conditions. Factors such as overloading, excessive extension, corrosion, or high-temperature exposure can shorten service life. Proper design and regular maintenance extend durability significantly.

When selecting extension springs, consider:

- Required load and deflection

- Maximum working extension

- Material and environmental factors

- Hook or end type for mounting

Fatigue life and cycle requirements

Consulting with an experienced spring manufacturer ensures the best fit for performance, safety, and cost-efficiency.

Not sure what extension spring you need? Review our Selection Guide for Extension Springs.

Heavy duty extension springs are often placed under heavy loads or operate in challenging environments. Components is known for providing expert design assistance that helps optimize the performance and lifetime of heavy duty extension springs. Our engineers can help you select the right material, manufacturing processes, and finishes to ensure your extension springs fit your application and meet performance requirements. Contact us for details.

What qualifies as a small extension spring varies depending on the application, but typically includes extension springs with ODs smaller than 0.500". Components offers small extension springs with ODs as small as 0.063" in our online store as well as custom extension springs with ODs made to your specifications. Shop small extension springs now or request a custom quote.

Stainless steel is one of the most popular spring materials. Stainless steel extension springs have exceptional strength and corrosion resistance, making them ideal for a variety of applications including medical, food service and preparation, marine, and more. offers food and medical-grade 316 stainless steel extension springs in our online store as well as custom stainless steel extension spring manufacturing.,

's extension springs are wound with an initial tension force which offers a small deflection load for secure installation âholdingâ. The initial tension is equal to the minimum force required to separate adjacent coils. Each spring is of the constant diameter type with a variety of hook/loop styles. Tolerances for extension spring rates depend upon the body diameter to wire diameter, but are usually +/- 10% and +/- 5% on the diameter. The initial tension is much more difficult to control and is offered as a reference value only.

Not sure what extension spring you need? Review our Selection Guide for Extension Springs.

Spring Anchors are also available.

Extension Spring Resources

Visit our to see tips and tricks for how to design and engineer extension springs and other Components parts.