Shop Online > Springs > Compression > Regular

S-106CS - 2.25" 302/304 Stainless Steel Compression Spring

|

Inventory:

|

|

| Estimated Lead Time | |

|---|---|

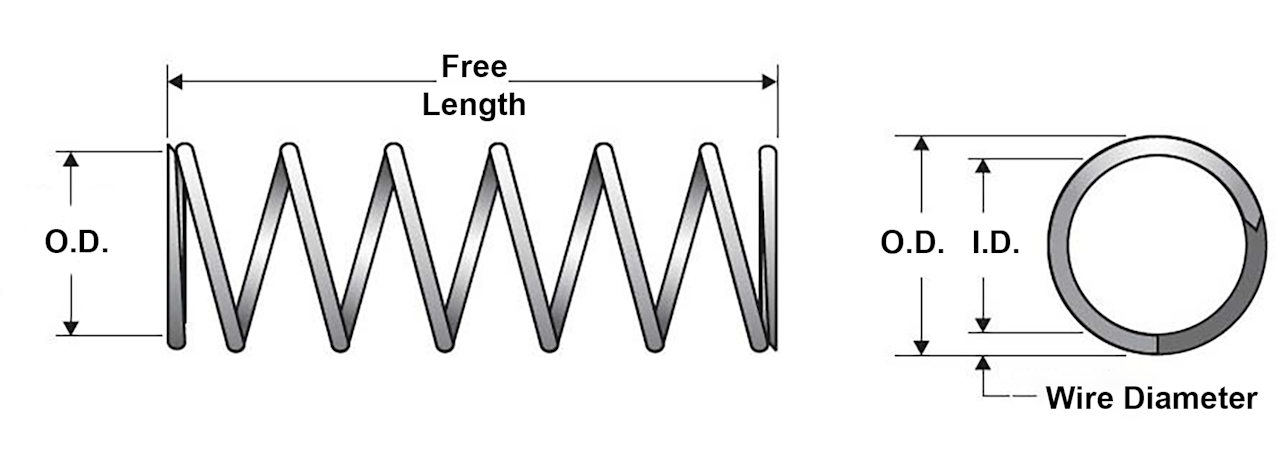

Compression spring manufactured from 302/304 stainless steel with 7.7 coils and closed & ground ends. This spring features an O.D. of 1", and an I.D. of 0.706".

| Label | Value |

|---|---|

| Brand | Century Spring |

| Display Name | S-106 |

| Ends | Closed & Ground |

| Finish | None |

| Free Length | 2.25 in |

| Inside Diameter | 0.706 in |

| Material | 302/304 Stainless Steel |

| Outside Diameter | 1 in |

| Part Type | Standard |

| Rate | 171 lbs/in |

| SKU | S-106CS |

| Solid Length | 1.135 in |

| Suggested Max Deflection | 0.502 in |

| Suggested Max Load | 86 lbf |

| Total Coils | 7.7 |

| Wire Diameter | 0.148 in |

| Label | Value |

|---|---|

| Brand | Century Spring |

| Display Name | S-106 |

| Ends | Closed & Ground |

| Finish | None |

| Free Length | 57.15 mm |

| Inside Diameter | 17.93 mm |

| Material | 302/304 Stainless Steel |

| Outside Diameter | 25.4 mm |

| Part Type | Standard |

| Rate | 29.94 N/mm |

| SKU | S-106CS |

| Solid Length | 28.83 mm |

| Suggested Max Deflection | 12.75 mm |

| Suggested Max Load | 382.53 N |

| Total Coils | 7.7 |

| Wire Diameter | 3.76 mm |

The S-106 compression spring is engineered for optimal performance in demanding applications. Constructed from high-quality 302/304 stainless steel and designed with precision and durability in mind, this spring is an essential component for a variety of mechanical systems where reliable force and resilience are paramount.

The S-106CS compression spring is designed with a free length of 0.75" total of 16 coils, and a rate of 0.87 lbs/in providing a balanced combination of flexibility and strength. This spring coil, and its closed & ground end configuration allows for efficient energy storage and release, making it suitable for applications requiring precise motion control.

The S-106 spring design is ideal for use in industrial machinery, automotive systems, and various mechanical assemblies where reliable force application is crucial. Its robust construction and thoughtful design make it a dependable choice for engineers seeking a high-performance spring solution.

The S-106CS compression spring is designed with a free length of 0.75" total of 16 coils, and a rate of 0.87 lbs/in providing a balanced combination of flexibility and strength. This spring coil, and its closed & ground end configuration allows for efficient energy storage and release, making it suitable for applications requiring precise motion control.

The S-106 spring design is ideal for use in industrial machinery, automotive systems, and various mechanical assemblies where reliable force application is crucial. Its robust construction and thoughtful design make it a dependable choice for engineers seeking a high-performance spring solution.