Shop Online > Fasteners > Screws > Captive Screws > Captive

753A - 10-32 UNF2A Aluminum Knurled Low Profile w/ Collar Head Captive Screw / Assembly

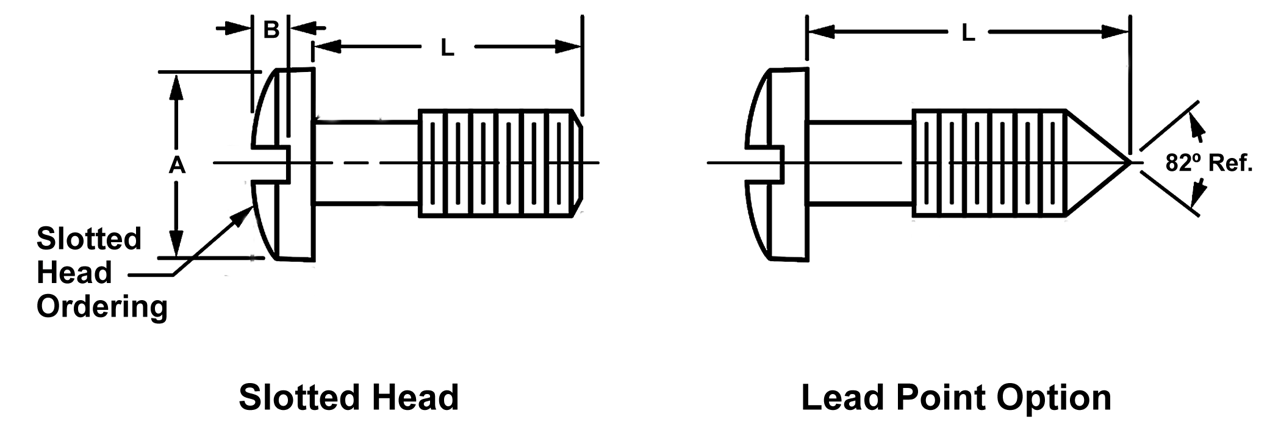

Configurable Knurled Low Profile w/ Collar head Slotted Aluminum captive screws with 10-32 UNF2A threads.

| Label | Value |

|---|---|

| Assembly | Configurable |

| Brand | Accurate Screw |

| Display Name | 753A |

| Drive Type | Slotted |

| End Diameter | 0.13 in |

| End Length | 0.125 in |

| End Type | Lead Point |

| Finish | None |

| Head Diameter | 0.5625 in |

| Head Height | 0.25 in |

| Knurl Pitch | 30 deg |

| Length L | 0.454 in |

| Material | Stainless Steel |

| Max L | 3 in |

| SKU | 753A |

| Screw Head Type | Knurled Low Profile |

| Shaft Diameter | 0.235 in |

| Shaft Length - Threaded | 0.375 in |

| Slot Depth | 0.0938 in |

| Slot Width | 0.0625 in |

| Thread Size | 5/16-24 |

| Label | Value |

|---|---|

| Assembly | Configurable |

| Brand | Accurate Screw |

| Display Name | 753A |

| Drive Type | Slotted |

| End Diameter | 3.3 mm |

| End Length | 3.18 mm |

| End Type | Lead Point |

| Finish | None |

| Head Diameter | 14.29 mm |

| Head Height | 6.35 mm |

| Knurl Pitch | 30 deg |

| Length L | 11.53 mm |

| Material | Stainless Steel |

| Max L | 76.2 mm |

| SKU | 753A |

| Screw Head Type | Knurled Low Profile |

| Shaft Diameter | 5.97 mm |

| Shaft Length - Threaded | 9.53 mm |

| Slot Depth | 2.38 mm |

| Slot Width | 1.59 mm |

| Thread Size | 5/16-24 |

Introducing the 753A Captive Screws, the perfect solution for securing panels and covers while allowing for quick access in various industrial applications. Crafted from high-quality aluminum, these captive screws are designed to provide durability and reliability in demanding environments.

The 753A Captive Screws are ideal for applications where frequent maintenance or access to the internal components is required. The aluminum material ensures a lightweight yet robust construction, making them suitable for use in aerospace, automotive, electronics, and other industries where weight is a critical factor.

These Captive Screws feature a sleek design with a finish that is both functional and aesthetically pleasing. The absence of finish adds a modern industrial look to the screws and eliminates the risk of chipping or flaking that can occur with painted finishes.

The unique captive design of these screws prevents them from getting lost or misplaced during maintenance procedures, saving time and effort for technicians and operators. The convenient captive feature also helps prevent foreign object debris (FOD) in sensitive equipment, ensuring a clean and safe working environment.

With their easy installation and removal process, the 753A Captive Screws streamline maintenance tasks and minimize downtime. Whether you are securing access panels on machinery or electronic enclosures, these screws offer a reliable and efficient solution.

In conclusion, the 753A Captive Screws stand out as a versatile and practical choice for professionals seeking secure and accessible fastening solutions. Invest in these aluminum Captive Screws to experience enhanced convenience and performance in your industrial applications.

The 753A Captive Screws are ideal for applications where frequent maintenance or access to the internal components is required. The aluminum material ensures a lightweight yet robust construction, making them suitable for use in aerospace, automotive, electronics, and other industries where weight is a critical factor.

These Captive Screws feature a sleek design with a finish that is both functional and aesthetically pleasing. The absence of finish adds a modern industrial look to the screws and eliminates the risk of chipping or flaking that can occur with painted finishes.

The unique captive design of these screws prevents them from getting lost or misplaced during maintenance procedures, saving time and effort for technicians and operators. The convenient captive feature also helps prevent foreign object debris (FOD) in sensitive equipment, ensuring a clean and safe working environment.

With their easy installation and removal process, the 753A Captive Screws streamline maintenance tasks and minimize downtime. Whether you are securing access panels on machinery or electronic enclosures, these screws offer a reliable and efficient solution.

In conclusion, the 753A Captive Screws stand out as a versatile and practical choice for professionals seeking secure and accessible fastening solutions. Invest in these aluminum Captive Screws to experience enhanced convenience and performance in your industrial applications.