Shop Online > Fasteners > Screws > Captive Screws > Captive

710A - 1/4-20 UNC2A Aluminum Knurled Head Captive Screw / Assembly

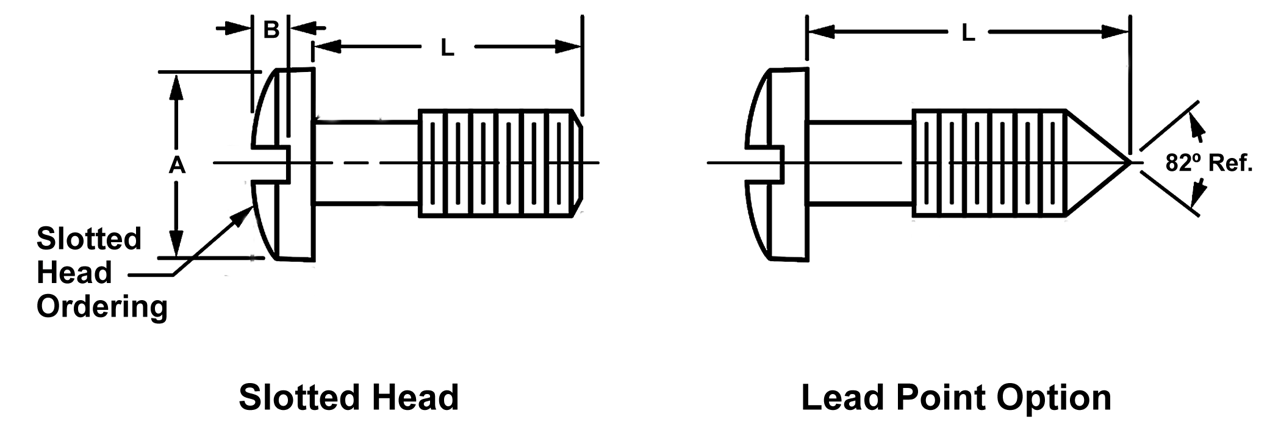

Configurable Knurled head Slotted Aluminum captive screws with 1/4-20 UNC2A threads.

| Label | Value |

|---|---|

| Assembly | Configurable |

| Brand | Accurate Screw |

| Chamfer Length | 0.038 in |

| Display Name | 710A |

| Drive Type | Slotted |

| End Diameter | 0.175 in |

| End Length | 0.1875 in |

| End Type | Lead Point |

| Finish | None |

| Head Diameter | 0.75 in |

| Head Height | 0.25 in |

| Knurl Pitch | 96 deg |

| Length L | 0.541 in |

| Material | Brass |

| Max L | 3 in |

| SKU | 710A |

| Screw Head Type | Knurled Low Profile |

| Shaft Diameter | 0.175 in |

| Shaft Length - Threaded | 0.375 in |

| Slot Depth | 0.125 in |

| Slot Width | 0.0625 in |

| Teeth Per Inch | 30.6 |

| Thread Size | 1/4-28 |

| Label | Value |

|---|---|

| Assembly | Configurable |

| Brand | Accurate Screw |

| Chamfer Length | 0.97 mm |

| Display Name | 710A |

| Drive Type | Slotted |

| End Diameter | 4.45 mm |

| End Length | 4.76 mm |

| End Type | Lead Point |

| Finish | None |

| Head Diameter | 19.05 mm |

| Head Height | 6.35 mm |

| Knurl Pitch | 96 deg |

| Length L | 13.74 mm |

| Material | Brass |

| Max L | 76.2 mm |

| SKU | 710A |

| Screw Head Type | Knurled Low Profile |

| Shaft Diameter | 4.45 mm |

| Shaft Length - Threaded | 9.53 mm |

| Slot Depth | 3.18 mm |

| Slot Width | 1.59 mm |

| Teeth Per Inch | 30.6 |

| Thread Size | 1/4-28 |

Introducing the 710A Captive Screws, the pinnacle of secure fastening solutions in the industrial realm. Crafted from high-grade aluminum, these captive screws boast unparalleled durability and strength while remaining lightweight for easy handling.

With a sleek finish that exudes professionalism, the 710A Captive Screws are designed to effortlessly blend into any machinery or equipment they are applied to. The absence of a finish provides a raw, industrial look that signals robustness and reliability.

Employing these aluminum captive screws simplifies maintenance procedures and enhances operational efficiency. Their captive design ensures that they remain attached to the equipment even when loosened, preventing loss or damage. This feature is especially valuable in high-vibration environments where traditional screws may come undone.

The 710A Captive Screws are a versatile solution for a wide range of applications, including automotive, aerospace, electronics, and machinery. Their non-magnetic properties make them ideal for use in sensitive electronic equipment where magnetic interference must be avoided.

These screws are a testament to precision engineering, with each thread meticulously cut to exacting standards to ensure a perfect fit every time. The aluminum construction not only offers excellent corrosion resistance but also makes them compatible with a variety of surface finishes and coatings.

In conclusion, the 710A Captive Screws are the go-to choice for engineers and manufacturers seeking a reliable, durable, and versatile fastening solution. Upgrade your equipment with these high-quality aluminum captive screws and experience the difference in performance and convenience.

With a sleek finish that exudes professionalism, the 710A Captive Screws are designed to effortlessly blend into any machinery or equipment they are applied to. The absence of a finish provides a raw, industrial look that signals robustness and reliability.

Employing these aluminum captive screws simplifies maintenance procedures and enhances operational efficiency. Their captive design ensures that they remain attached to the equipment even when loosened, preventing loss or damage. This feature is especially valuable in high-vibration environments where traditional screws may come undone.

The 710A Captive Screws are a versatile solution for a wide range of applications, including automotive, aerospace, electronics, and machinery. Their non-magnetic properties make them ideal for use in sensitive electronic equipment where magnetic interference must be avoided.

These screws are a testament to precision engineering, with each thread meticulously cut to exacting standards to ensure a perfect fit every time. The aluminum construction not only offers excellent corrosion resistance but also makes them compatible with a variety of surface finishes and coatings.

In conclusion, the 710A Captive Screws are the go-to choice for engineers and manufacturers seeking a reliable, durable, and versatile fastening solution. Upgrade your equipment with these high-quality aluminum captive screws and experience the difference in performance and convenience.