Shop Online > Springs > Compression > Regular

61226SCS - 1.5" 316 Stainless Steel Compression Spring

|

Inventory:

|

|

| Estimated Lead Time | |

|---|---|

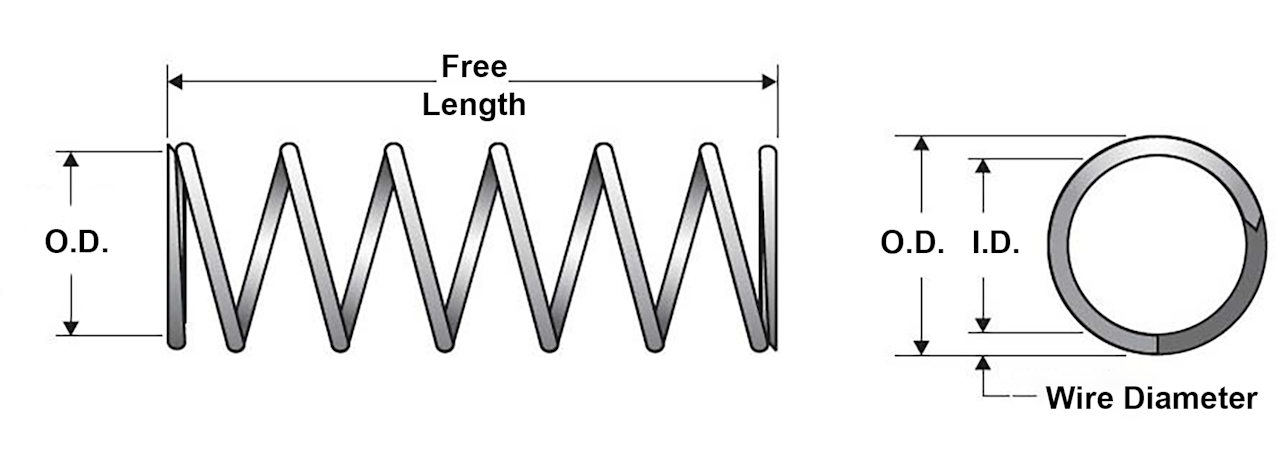

Compression spring manufactured from 316 stainless steel with 40.4 coils and closed & ground ends. This spring features an O.D. of 0.12", and an I.D. of 0.076".

| Label | Value |

|---|---|

| Brand | Century Spring |

| Display Name | 61226S |

| Ends | Closed & Ground |

| Finish | Passivated |

| Free Length | 1.5 in |

| Inside Diameter | 0.076 in |

| Material | 316 Stainless Steel |

| Outside Diameter | 0.12 in |

| Part Type | Standard |

| Rate | 8.1 lbs/in |

| SKU | 61226SCS |

| Solid Length | 0.9 in |

| Suggested Max Deflection | 0.322 in |

| Suggested Max Load | 2.608 lbf |

| Total Coils | 40.4 |

| Wire Diameter | 0.022 in |

| Label | Value |

|---|---|

| Brand | Century Spring |

| Display Name | 61226S |

| Ends | Closed & Ground |

| Finish | Passivated |

| Free Length | 38.1 mm |

| Inside Diameter | 1.93 mm |

| Material | 316 Stainless Steel |

| Outside Diameter | 3.05 mm |

| Part Type | Standard |

| Rate | 1.42 N/mm |

| SKU | 61226SCS |

| Solid Length | 22.86 mm |

| Suggested Max Deflection | 8.18 mm |

| Suggested Max Load | 11.6 N |

| Total Coils | 40.4 |

| Wire Diameter | 0.56 mm |

The 61226S compression spring is engineered for optimal performance in demanding applications. Constructed from high-quality 316 stainless steel and designed with precision and durability in mind, this spring is an essential component for a variety of mechanical systems where reliable force and resilience are paramount.

The 61226SCS compression spring is designed with a free length of 1.25" total of 33.8 coils, and a rate of 9.8 lbs/in providing a balanced combination of flexibility and strength. This spring coil, and its closed & ground end configuration allows for efficient energy storage and release, making it suitable for applications requiring precise motion control.

The 61226S spring design is ideal for use in industrial machinery, automotive systems, and various mechanical assemblies where reliable force application is crucial. Its robust construction and thoughtful design make it a dependable choice for engineers seeking a high-performance spring solution.

The 61226SCS compression spring is designed with a free length of 1.25" total of 33.8 coils, and a rate of 9.8 lbs/in providing a balanced combination of flexibility and strength. This spring coil, and its closed & ground end configuration allows for efficient energy storage and release, making it suitable for applications requiring precise motion control.

The 61226S spring design is ideal for use in industrial machinery, automotive systems, and various mechanical assemblies where reliable force application is crucial. Its robust construction and thoughtful design make it a dependable choice for engineers seeking a high-performance spring solution.