Shop Online > Springs > Compression > Regular

3506CS - 0.53" Music Wire Compression Spring

|

Inventory:

|

|

| Estimated Lead Time | |

|---|---|

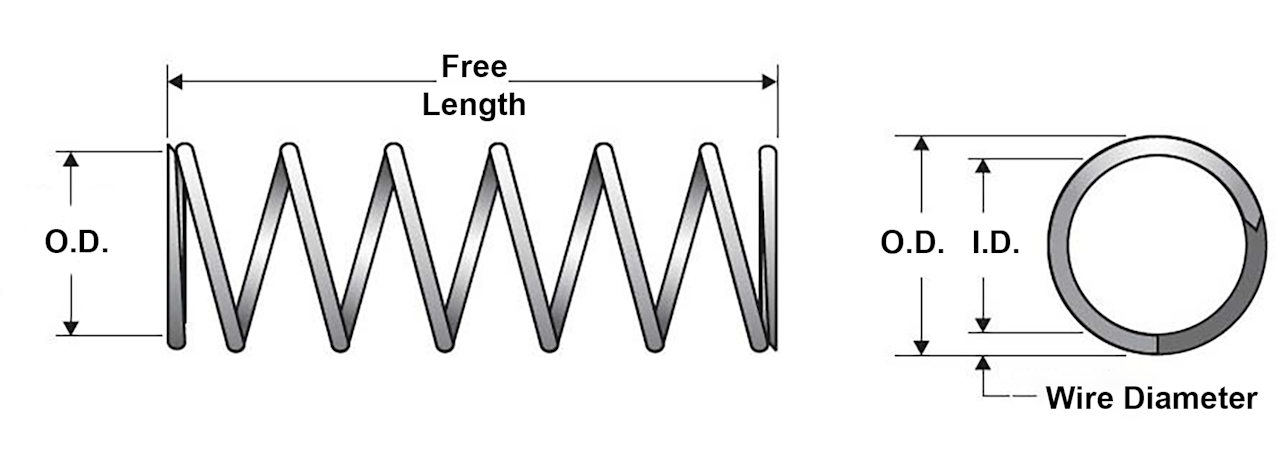

Compression spring manufactured from music wire with 3 coils and closed ends. This spring features an O.D. of 0.625", and an I.D. of 0.569".

NOTE: The spring rate value for compression springs with 4 coils or less is a reference value.

| Label | Value |

|---|---|

| Brand | Century Spring |

| Display Name | 3506 |

| Ends | Closed |

| Finish | Zinc |

| Free Length | 0.53 in |

| Inside Diameter | 0.569 in |

| Material | Music Wire |

| Outside Diameter | 0.625 in |

| Part Type | Standard |

| Rate | 4.2 lbs/in |

| SKU | 3506CS |

| Solid Length | 0.11 in |

| Suggested Max Deflection | 0.42 in |

| Suggested Max Load | 1.7 lbf |

| Total Coils | 3 |

| Wire Diameter | 0.028 in |

| Label | Value |

|---|---|

| Brand | Century Spring |

| Display Name | 3506 |

| Ends | Closed |

| Finish | Zinc |

| Free Length | 13.46 mm |

| Inside Diameter | 14.45 mm |

| Material | Music Wire |

| Outside Diameter | 15.88 mm |

| Part Type | Standard |

| Rate | 0.74 N/mm |

| SKU | 3506CS |

| Solid Length | 2.79 mm |

| Suggested Max Deflection | 10.67 mm |

| Suggested Max Load | 7.56 N |

| Total Coils | 3 |

| Wire Diameter | 0.71 mm |

The 3506CS compression spring is a meticulously engineered component designed for a wide range of industrial applications requiring reliable performance and durability. Crafted from premium 0.028" diameter music wire, the 3506 spring design exhibits reliable strength across its 3 active coils, withstanding repeated compression cycles with a maximum load of 1.7 lbf without succumbing to fatigue.

We manufacture the 3506 design to provide a compression spring that is 0.53" long at rest and provides a consistent rate of 4.2 lbs/in along its recommended maximum of 0.42" deflection. For best results, your application should fully accommodate the inner (0.569") and outer (0.625") diameters of this spring and be designed for its closed end configuration.

We manufacture the 3506 design to provide a compression spring that is 0.53" long at rest and provides a consistent rate of 4.2 lbs/in along its recommended maximum of 0.42" deflection. For best results, your application should fully accommodate the inner (0.569") and outer (0.625") diameters of this spring and be designed for its closed end configuration.